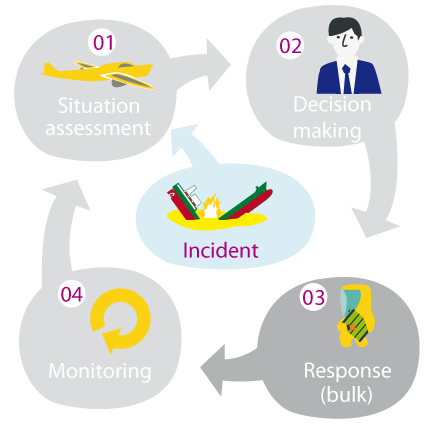

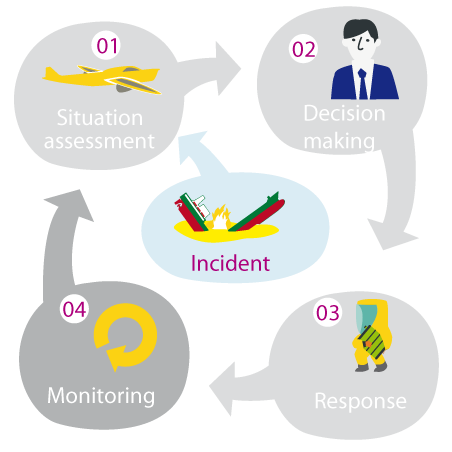

The choice of response strategy is essentially dictated by three criteria:

Varying degrees of response may be required:

prevention measures, monitoring of the spreading of

the pollution and/or clean-up actions.

As the situation may evolve very quickly, the chosen

strategy must be adjusted according to the reality in

the field.

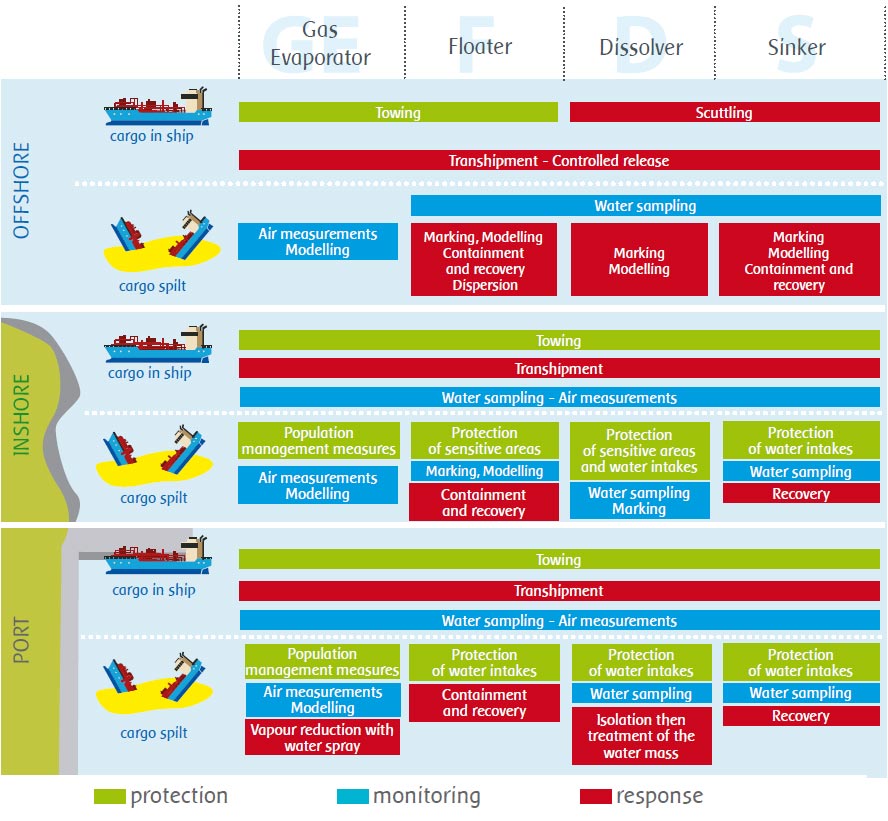

Towing the ship

When a vessel carrying HNS is in difficulty offshore, it may be towed to a place of refuge, i.e. a place where the situation can be stabilized while minimizing the environmental impact. On the other hand, if the incident occurs in a coastal or port area and the cargo onboard the ship presents too high a risk for nearby populations, it may be towed offshore to be lightered• or even scuttled•.

In 2012, in the Persian Gulf, the chemical tanker Stolt Valor, carrying hazardous substances, suffered an explosion followed by a fire which lasted 5 days. The vessel in distress was taken in tow and was in search of a place of refuge. Three countries denied the tanker access to one of their ports: Qatar, Saudi Arabia and Bahrain. Obtaining access to a place of refuge for a vessel in difficulty is a problematic issue. Finally, Saudi Arabia granted the Stolt Valor permission to anchor off its coasts. Once the cargo of hazardous substances had been transferred, the wreck was towed away and dismantled.

Defining the exclusion zone

Generally speaking, an exclusion zone is defined around

the vessel prohibiting shipping traffic, fishing and overflights

in the hazard area. If the substance spilt is a

gas or an evaporator, it may form a toxic cloud which

presents a danger for nearby populations. In this

case, computer modelling provides valuable information

on the dispersion and movement of the cloud

of pollution, helping to determine the measures to

be taken in terms of local populations.

Protecting sensitive areas

If a floating substance is spilt in a coastal area, floating or filter booms resistant to the pollutant must be deployed. This will protect ecologically or economically sensitive areas such as ports, fish farms, marshes and bird reserves.

Protecting water intakes

If the spill occurs in a coastal or port area, one of the

priorities will be to protect water intakes to prevent

the pollutant from entering sites or installations that

use seawater (fish farms, factories).

In addition to shutting down pumps, different types

of plugging or filtering systems can be deployed to

protect water intakes: inflatable plugs•, drain covers

or even sometimes more unexpected materials

(e.g. wire mesh, straw).

It is important to monitor the pollution in order to track changes to the situation and adjust the response strategy if the initial approach proves to be ineffective or inappropriate. The transfer of information to response coordinators is a key stage.

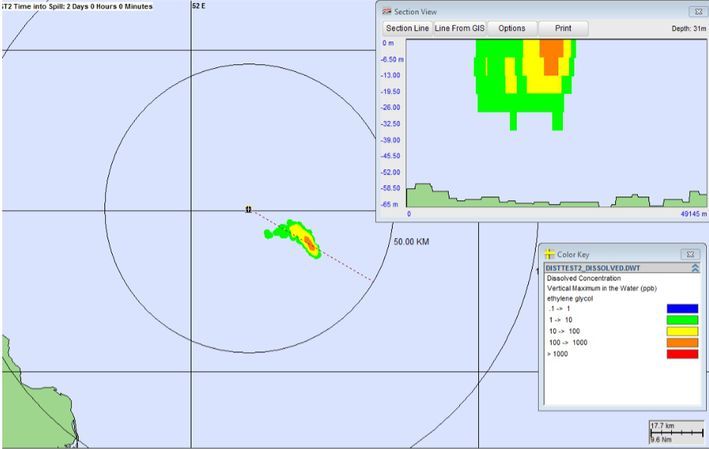

Modelling

Together with marking, computer modelling performed during the risk assessment is used to monitor the pollution throughout the response phase. Through modelling, hazards for operators can be predicted and optimal response conditions can be ensured in the case of a release of gases or evaporators.

Measurements and samples

Generally speaking, when a non-floating chemical is spilt or liable to be spilt, the response options are rather limited, especially in the open sea.

When the Ievoli Sun accident occurred in the English Channel in 2000, a cargo monitoring system was set up as small leaks of styrene, a

hazardous floater/evaporator, were detected from the wreck.

Air and water samples were taken around the vessel and regularly analysed for several

months by the French Navy laboratory in Cherbourg. Ifremer• also implemented a

sampling plan to monitor the quality of the marine environment (water column and living

organisms). The different analyses conducted

did not show any contamination by styrene.

Meanwhile, during the first weeks following

the accident, the Marseille Navy Fire Department

and a Civil Protection Unit set up a

network on land to detect styrene vapours

in the atmosphere, giving rise to negative

results.

The pollution should be monitored via air measurements

and water, sediment and/or living organism

samples. These actions follow on from the analyses

performed during the initial risk assessment phase.

Marking

It is often difficult, or even impossible, to observe a

chemical pollutant spilt at sea. It is therefore essential

to mark the pollution so as to identify it more

easily, to monitor its movements and to regularly

update drift• predictions.

In coastal areas, certain dyes (organol red, fluorescein)

can be used to track the movements of invisible

pollution.

However, there are two

limiting factors: marking

can rarely be carried out

at the beginning of the

spill and the behaviour

of the dye is not always

identical to that of the

pollutant. We therefore

refer to the probability

area where the

substance spilt is likely

to be found.

The slicks formed by floating products can also be

identified using marker buoys deployed from an

aircraft or a vessel. These buoys can then be located

via different systems (satellite-tracked buoys, GPS• buoys).

Transhipment

When a ship is grounded, on a reef or sand bank for example, in order to refloat the ship its cargo must often be transhipped• to make the ship as light as possible. In the case of a wreck that has sunk with its cargo, the pollutant may be removed by pumping it to a surface vessel.

In 1996, the gas carrier Igloo Moon ran aground south of Florida. Due to the shallow waters, the fuel was first pumped out, then 15 % of the cargo of liquefied butadiene was transferred to another ship: Selma Kosan. The ballast• water was discharged into the sea following decontamination. It was not until after these lightering operations that the Igloo Moon could be refloated.

Controlled release

If the product entails only a low risk for humans and the environment, it may be possible to release it into the environment in a controlled manner, thereby diluting it in a large quantity of seawater. This technique must not be used in coastal or port areas, as dilution is too low and the risk for populations too high.

In 2000, the chemical tanker Ievoli Sun sank

in the English Channel, in waters 70 m deep

with its cargo of 3,998 tonnes of styrene,

1,027 tonnes of methylethylketone• and

996 tonnes of isopropyl alcohol•.

In order to define the most appropriate response

strategy, experiments were conducted, mainly

by Cedre, on the styrene from the Ievoli Sun.

These experiments showed that this product,

which is dangerous for the environment, did

not present a risk of sudden polymerization.

Pumping operations were conducted.

The methylethylketone and the isopropyl

alcohol, which are soluble substances that are

totally biodegradable• and have little environmental

impact, were released in a controlled

manner into the environment.

The treatment of the wreck of the Ievoli Sun

required the assistance of a remote-controlled

underwater robot which was used for subsea

observations and to drill holes in the hull to

enable pumping and controlled release of the

cargo.

Scuttling

Taking a more radical approach, it is possible to consider sinking the cargo offshore, if it is too dangerous to allow intervention. This solution involves scuttling• the vessel.

In 2003, the bulk carrier Adamandas, at anchor near a port on Réunion Island, turned into a potential bomb due to the rising temperature of its cargo (up to 300°C) together with the release of dihydrogen. The French authorities decided to scuttle the vessel using explosives, 20 km off the coast.